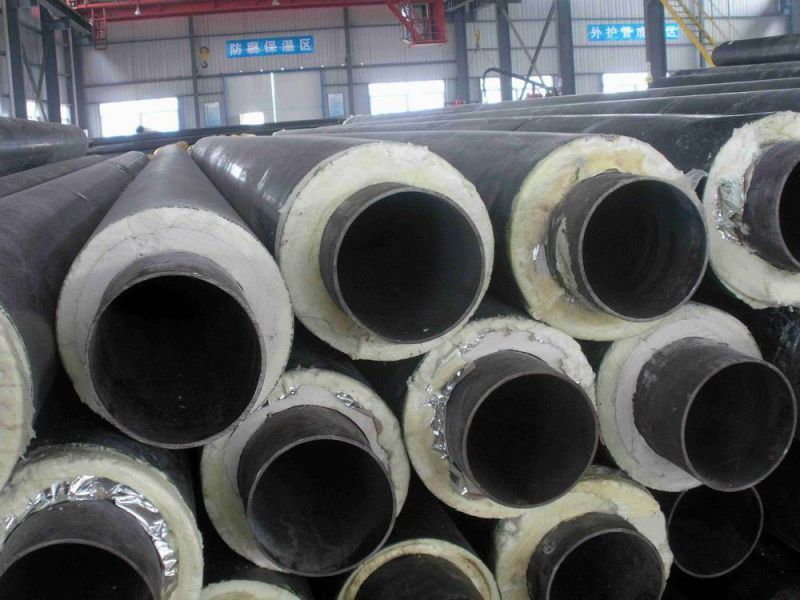

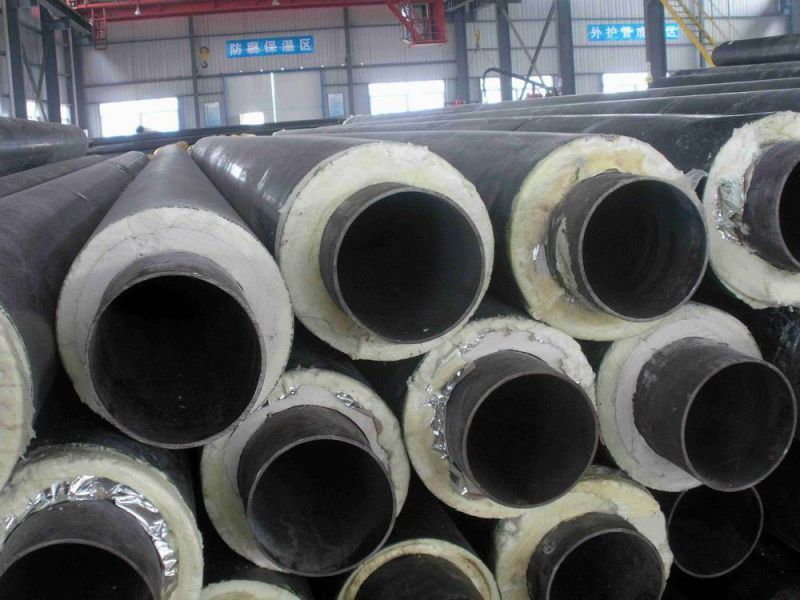

聚氨酯保溫管道的構(gòu)造機理

Structure mechanism of polyurethane insulation pipeline

1.防腐層:維護外鋼管防止腐蝕物腐蝕鋼管,延伸鋼管運用壽命。

1. Anti-corrosive coating: Maintain external steel pipe to prevent corrosion of steel pipe and extend service life of steel pipe.

2.外護鋼管: 維護保溫層免受地下水腐蝕,支撐任務(wù)管并能接受一定的內(nèi)部荷載,保證任務(wù)管正常任務(wù)。

2. External protection steel pipe: Maintain insulation layer from groundwater corrosion, support task pipe and accept certain internal load, ensure the normal task of task pipe.

3.聚氨酯泡沫層: 保證介質(zhì)溫度,保證外護管外表堅持常溫。

3. polyurethane foam layer: ensure the medium temperature, ensure the external tube surface to adhere to normal temperature.

4.阻隔、反射層: 保證無機泡沫資料不進入無機硬質(zhì)耐低溫層;反射耐低溫層局部熱量。

4. barrier, reflective layer: ensure that inorganic foam data do not enter the inorganic hard and low temperature resistant layer; reflect the local heat of low temperature resistance.

5.無機硬質(zhì)保溫層:耐低溫,保證與無機保溫層之間的界面溫度,保證泡沫不被炭化。

5. inorganic hard insulation layer: low temperature resistance, ensure the interface temperature between inorganic insulation layer and ensure that the foam is not carbonized.

6.減阻層: 保證任務(wù)鋼管熱脹冷縮自在運動。

6. Drag Reduction Layer: Guarantee the free movement of the task steel tube during thermal expansion and contraction.

7.任務(wù)鋼管:保證保送介質(zhì)正常活動。

7. Task Steel Pipe: Ensure the normal activities of the delivery medium.

當今社會城鄉(xiāng)建造展開矯捷,跟著國力的加強,供熱管道保溫也在不時的行進,建議動力節(jié)省,增添熱能喪失,下降工程本錢成爲供熱管道保溫控制造業(yè)的一大展開趨向。

Nowadays, the construction of urban and rural areas is flexible. With the strengthening of national strength, heat preservation of heating pipelines is also going on from time to time. It is suggested that power saving, heat loss increase and project cost reduction become a major trend of heat preservation control of heating pipelines.

In summary, all the above-mentioned Shandong Hipper Pipe Technology Development Co., Ltd. provides, want to know more about polyurethane insulation pipe manufacturers, welcome to pay attention to our website: http://www.qndr49.cn Thank you for your support!